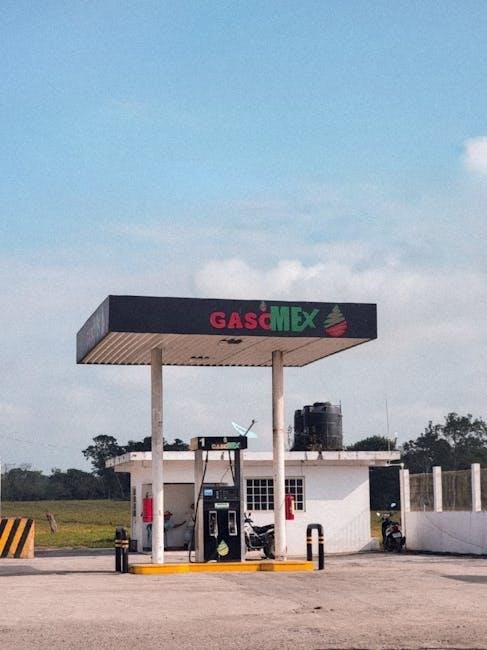

Manual gas pumps are essential tools for fuel transfer, offering reliability in remote or off-grid locations․ They ensure safe handling of flammable fuels and provide a stable setup for efficient operation․ Designed with basic mechanisms, these pumps are ideal for emergency scenarios and industrial applications, making them a versatile solution for fuel management needs․

Overview of Manual Gas Pumps

Manual gas pumps are portable, non-electric devices designed for transferring fuels like gasoline, diesel, or liquefied petroleum gas․ They operate via a piston-and-cylinder mechanism, requiring physical effort to create suction and discharge fuel․ These pumps are ideal for remote locations, emergency scenarios, or small-scale industrial applications where electricity is unavailable․ Their simplicity and durability make them a reliable choice for safe and efficient fuel handling․ Unlike electric pumps, manual gas pumps are cost-effective and require minimal maintenance, making them a practical solution for various fuel transfer needs․ They are widely used in agricultural, marine, and off-grid settings, ensuring consistent fuel supply without dependency on power sources․

Importance of Manual Gas Pumps in Fuel Transfer

Manual gas pumps play a crucial role in fuel transfer, especially in scenarios where electricity is unavailable or unreliable․ They provide a dependable method for transferring flammable liquids safely and efficiently․ In remote or off-grid locations, these pumps are essential for ensuring a steady fuel supply for vehicles, machinery, and generators․ Their portability and ease of use make them ideal for emergency situations, such as natural disasters or power outages, where access to fuel is critical․ Additionally, manual gas pumps are cost-effective and require minimal maintenance, making them a practical solution for both industrial and agricultural applications․ They ensure that fuel transfer operations remain uninterrupted, even in challenging conditions, highlighting their importance as a reliable backup option․

A manual gas pump consists of a piston and cylinder, inlet and outlet valves, a handle mechanism, and a hose system․ These components work together to facilitate efficient fuel transfer, ensuring reliable operation and durability in various applications․ The piston and cylinder mechanism creates suction to draw fuel, while the valves control flow direction․ The handle provides the mechanical force needed for operation, and the hose system delivers fuel safely to the target container․ Together, these parts ensure smooth and consistent fuel transfer, making manual gas pumps a practical solution for different fueling needs․ The piston and cylinder mechanism is the heart of a manual gas pump, enabling fuel transfer through a simple yet effective process․ As the handle is moved up and down, the piston inside the cylinder creates suction, drawing fuel from the source․ This motion forces the fuel through the outlet valve and into the hose, delivering it to the desired location․ The mechanism relies on precise engineering to ensure smooth operation and minimal leakage․ Made from durable materials, this system withstands regular use and varying fuel types, making it a reliable component for efficient fuel transfer in various applications․ The inlet and outlet valves are critical components of a manual gas pump, ensuring the smooth flow of fuel during transfer․ The inlet valve allows fuel to enter the pump’s cylinder from the source, while the outlet valve directs the fuel out through the hose to the desired location․ These valves operate in sync with the piston mechanism, opening and closing to maintain consistent flow and prevent backflow․ Made from durable materials like metal or high-grade plastics, they are designed to withstand various fuel types and pressures․ Proper functioning of these valves is essential for efficient, leak-free operation and safe fuel transfer in industrial, agricultural, or emergency scenarios․ The handle mechanism of a manual gas pump is designed to provide a comfortable grip and efficient leverage, enabling easy operation․ Typically made of durable materials like metal or high-strength plastic, the handle is ergonomically shaped to reduce fatigue during prolonged use․ The hose system, usually constructed from flexible rubber or PVC, connects the pump to the fuel source and the target container․ It is designed to withstand fuel exposure and environmental conditions, ensuring reliable performance․ The handle’s motion translates to the piston’s movement, creating suction and pressure to transfer fuel through the hose․ This system ensures precise control over fuel flow, making it essential for safe and efficient operation․ Operating a manual gas pump involves ensuring a firm, level surface, squeezing the handle to transfer fuel, and following safety procedures to prevent spills and accidents․ Before operating a manual gas pump, ensure the surface is firm and level to prevent accidents․ Check for guards and obstacles around the pump to ensure safe operation․ Always follow safety guidelines, such as not smoking or exposing the area to open flames, as flammable fuels pose significant risks․ Read the operating manual thoroughly and familiarize yourself with the pump’s components․ Ensure proper ventilation in the area to avoid gas fumes accumulation․ Wear appropriate protective gear, including gloves and safety glasses, to minimize risks․ Never leave the pump unattended during operation, and ensure all connections are secure to prevent leaks or spills․ These steps are critical for safe and efficient fuel transfer․ To begin, ensure the manual gas pump is securely positioned and the area is clear of obstacles․ Attach the suction hose to the fuel source and the discharge hose to the target container․ Open the valve to allow fuel flow and start pumping by moving the handle up and down rhythmically․ This creates suction, drawing fuel through the hose․ Monitor the fuel level in the container to avoid overfilling․ Once the desired amount is transferred, close the valve and disconnect the hoses․ Always maintain a safe distance from open flames and ensure proper ventilation to prevent fume accumulation; This method ensures efficient and secure fuel transfer․ After completing the fuel transfer, relieve any remaining pressure in the system by slowly releasing the handle․ Close the inlet and outlet valves to isolate the pump from the fuel source and container․ Drain any residual fuel from the hose into an approved container to prevent spills․ Clean the pump and surrounding area to remove dirt or fuel residue․ Store the pump in a dry, well-ventilated space, away from ignition sources or flammable materials․ Secure the pump to prevent unauthorized use or tampering․ Regularly inspect the pump and hoses for wear or damage before storing․ Proper post-operation care ensures safety and extends the pump’s lifespan․ Handling flammable fuels requires strict adherence to safety protocols to prevent accidents․ Ensure a stable setup, avoid sparks, and use proper grounding to minimize risks․ Always follow safety guidelines․ Handling flammable fuels safely is crucial to prevent accidents․ Always store fuels in well-ventilated, approved containers away from ignition sources․ Ensure the pump is on a level, stable surface and properly grounded to avoid static electricity․ Keep emergency equipment like fire extinguishers nearby․ Never smoke or use open flames while operating the pump․ Regularly inspect hoses and connections for leaks or damage․ In case of spills, immediately contain them and clean up thoroughly․ Follow all safety guidelines provided in the pump’s manual to ensure safe operation and minimize risks associated with flammable fuels․ Preventing accidents begins with a stable setup․ Ensure the pump is placed on a firm, level surface to avoid tipping․ Check the surrounding area for obstructions or hazards, such as loose debris or uneven ground․ Secure the pump and hoses properly to prevent movement during operation․ Always ensure the pump is on a non-slip surface or use anti-vibration pads if necessary․ Keep the area clear of flammable materials and ignition sources․ Regularly inspect the pump’s components, such as hoses and connections, for wear or damage․ Use wheel chocks if the pump is mounted on a vehicle․ These steps help ensure a safe and accident-free fuel transfer process․ In case of a leak or spill, immediate action is crucial to prevent accidents․ First, stop the pump operation and isolate the area to prevent ignition sources․ Evacuate the surrounding area and ensure proper ventilation to avoid vapor buildup․ Use absorbent materials or spill kits to contain the leak and prevent fuel from spreading․ Do not attempt to operate electrical devices nearby․ Notify emergency services if the situation is severe․ Once the spill is controlled, clean the area thoroughly with appropriate materials․ Dispose of contaminated substances according to local regulations․ Always refer to the pump’s manual for specific emergency instructions to ensure safety and minimize environmental impact․ Regular inspection and cleaning of manual gas pumps are essential for optimal performance․ Periodic lubrication of moving parts and timely replacement of worn components ensure longevity and reliability․ Regular inspection and cleaning are crucial for maintaining the efficiency and safety of manual gas pumps․ Users should inspect all components, including the piston, valves, and hoses, for signs of wear or damage․ Cleaning involves removing dirt and debris that might obstruct fuel flow or cause mechanical issues․ Proper lubrication of moving parts ensures smooth operation․ It’s important to follow the manufacturer’s guidelines for cleaning and maintenance to prevent malfunctions․ Regular servicing can extend the lifespan of the pump and ensure reliable performance in various applications, from industrial to emergency fuel transfer scenarios․ This routine upkeep is vital for safe and effective fuel management․ Manual gas pumps can experience issues such as leaks, blockages, or worn-out seals, which may hinder their performance․ Leaks often occur around the piston or O-rings, while blockages can develop in the hose or nozzle․ DIY repairs include replacing damaged O-rings or seals with compatible replacements․ Cleaning the pump’s inlet valve and hose can resolve blockages caused by debris․ If the handle becomes stiff, lubricating the joints with oil or grease can restore smooth operation․ For more complex issues, users may need to dismantle the pump to access internal components․ Always refer to the manual for specific repair guidance and ensure safety by wearing gloves and working in a well-ventilated area․ Regular maintenance can prevent such problems․ Regular lubrication of moving parts in a manual gas pump is essential to ensure smooth operation and extend its lifespan․ Apply silicone-based grease to the piston, cylinder, and handle joints every 50 hours of use or as needed․ Inspect and replace worn-out seals, O-rings, and gaskets to prevent leaks․ Check the inlet and outlet valves for proper sealing and replace them if necessary․ Lubricate the pump’s bearings annually to maintain efficiency․ Replace any corroded or damaged components promptly․ Always follow the manufacturer’s guidelines for lubrication and part replacement to ensure optimal performance and safety․ Regular maintenance helps prevent breakdowns and ensures reliable fuel transfer․ Manual gas pumps are widely used in remote areas, industrial settings, and agricultural applications for fuel transfer; They are reliable in emergency scenarios and off-grid locations․ Manual gas pumps are indispensable in remote or off-grid locations where electricity is unavailable․ Their simplicity and reliability make them ideal for fuel transfer in isolated areas․ These pumps operate without power, ensuring continuous fuel supply for vehicles, equipment, and generators․ They are lightweight, portable, and easy to use, making them perfect for farms, rural communities, or emergency response scenarios․ The absence of complex electronics ensures durability and minimal maintenance, crucial in areas with limited access to repair services․ Additionally, their ability to handle flammable fuels safely in challenging environments makes them a vital tool for remote operations and disaster recovery efforts․ Manual gas pumps play a crucial role in industrial and agricultural settings, where efficient fuel transfer is essential․ In factories and farms, these pumps are used to refuel machinery, generators, and vehicles, ensuring uninterrupted workflow․ Their durability and ease of operation make them suitable for heavy-duty tasks, while their portability allows for quick relocation between work sites․ Additionally, manual pumps are often used for transferring oils, lubricants, and other fluids in industrial processes․ Farmers rely on them for fueling tractors and equipment, especially in areas where electric pumps are impractical․ This versatility ensures they remain a vital asset in both industrial and agricultural operations, supporting productivity and efficiency․ Manual gas pumps are indispensable in emergency fuel transfer scenarios, particularly during natural disasters or power outages․ They provide a reliable means to transfer fuel without electricity, ensuring backup generators and critical vehicles remain operational․ Their simplicity and portability make them ideal for disaster response, where quick access to fuel is essential․ In remote areas or when electric pumps fail, manual pumps serve as a lifeline, enabling the distribution of fuel to support rescue operations and maintain essential services․ Their durability and ease of use ensure they can handle high-stress situations, making them a vital tool for emergency preparedness and response efforts․

Key Components of a Manual Gas Pump

Piston and Cylinder Mechanism

Inlet and Outlet Valves

Handle Mechanism and Hose System

Operating a Manual Gas Pump

Pre-Operation Checks and Safety Measures

Step-by-Step Fuel Transfer Process

Stopping and Securing the Pump Post-Operation

Safety Considerations

Handling Flammable Fuels Safely

Preventing Accidents and Ensuring Stable Setup

Emergency Procedures in Case ofLeaks or Spills

Emergency Procedures in Case of Leaks or Spills

Maintenance and Troubleshooting

Regular Inspection and Cleaning

Common Issues and DIY Repairs

Periodic Lubrication and Part Replacement

Applications of Manual Gas Pumps

Use in Remote or Off-Grid Locations

Industrial and Agricultural Applications

Emergency Fuel Transfer Scenarios

Leave a Reply

You must be logged in to post a comment.